How To Tan Salmon Skin

TANNED FISH SKIN¶

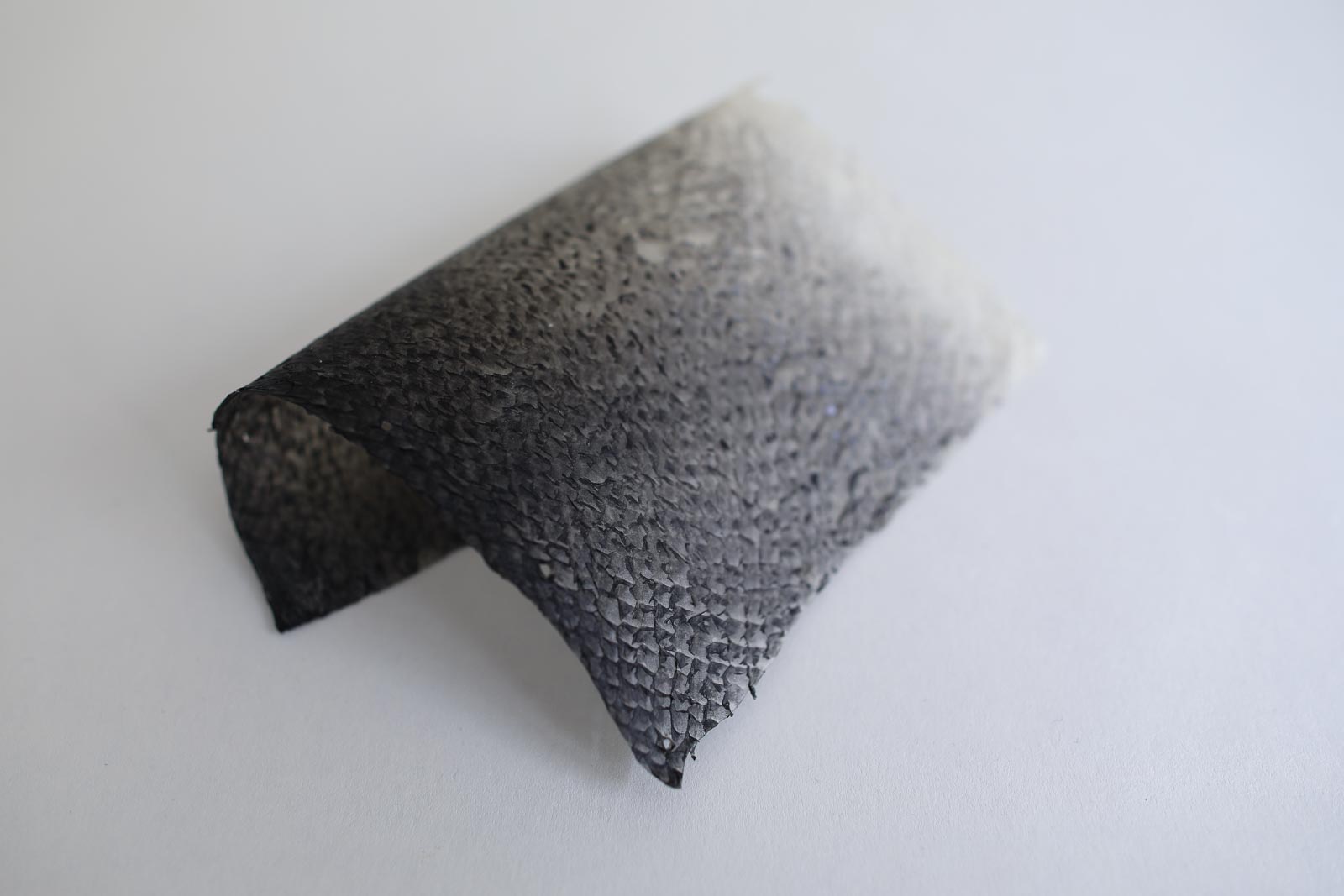

Tanned salmon skin without using glycerine as softener (post-handling), Loes Bogers, 2020

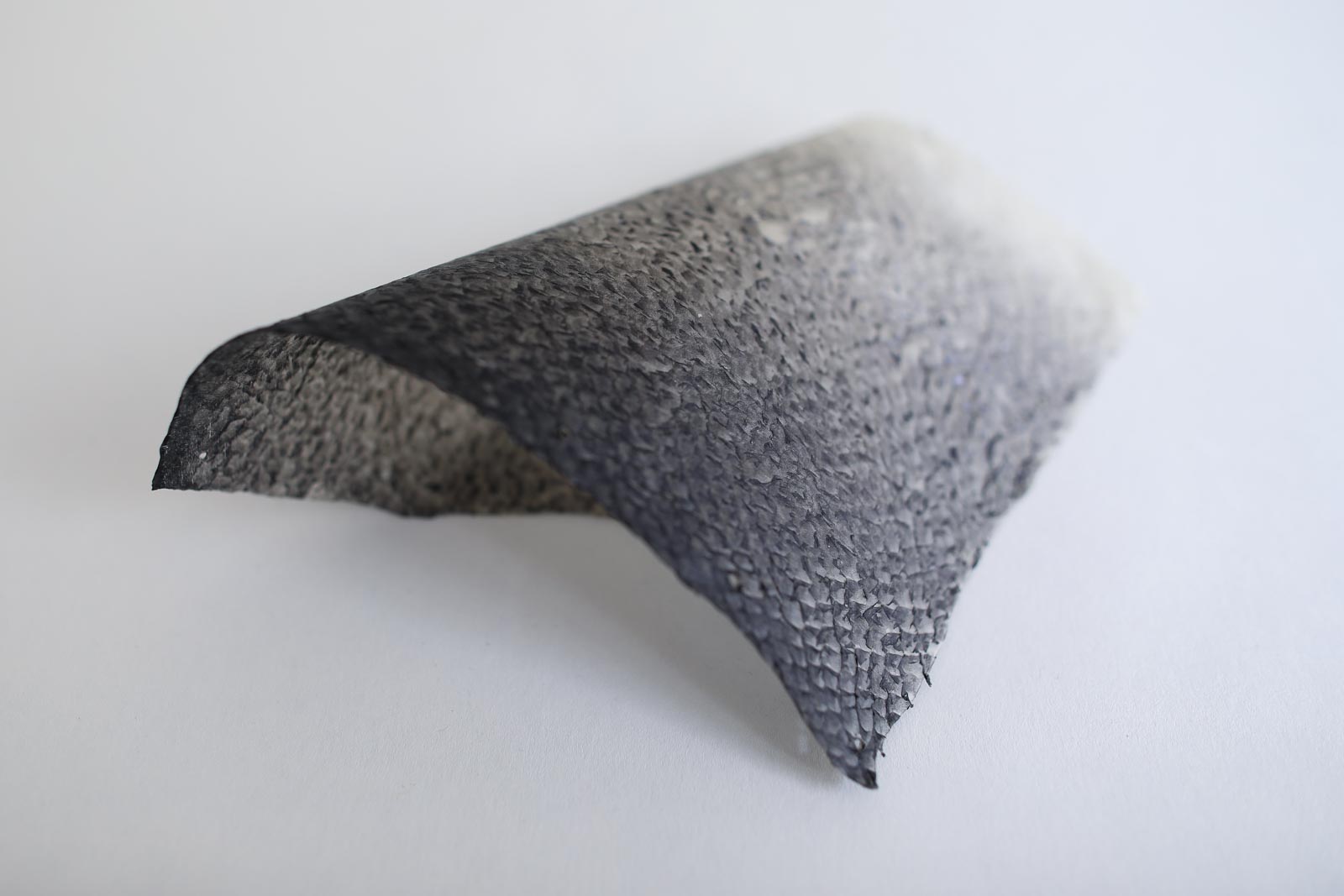

Tanned salmon peel with glycerine practical as softener (post-treatment), Loes Bogers, 2020

General INFORMATION¶

Very strong, translucent tanned fish skin that varies from stiff and a little rigid to flexible/soft and malleable when treated with a softener. The feeling of this tanned and dried fish skin is more like thick paper than leather of cow hide. It has a similar braking surface friction. Information technology is thinner than leather of mammal hibernate, but equally potent if not stronger.

Physical form

Surfaces

Color without additives: colour of the fish skin

Fabrication fourth dimension

Preparation time: i Hours

Processing time: ane week

Need attention: every 2 hours, to shake the jar (the kickoff 3 days)

Last form accomplished after: 1 calendar week

Estimated price (consumables)

one,10 Euros, for a yield of approx. 400 ml tanning liquid that is used one time (cost of the liquid is virtually 3,xxx euros but tin can exist used at least 3 times, if non more). Fish skins can exist obtained for free as waste from friendly local fish mongers.

RECIPE¶

Ingredients¶

- Fresh uncooked fish skins, e.g. salmon skins

- the amounts below are plenty for 1 large fish skin

- Denatured alcohol 96% - 200 ml

- stabilizer: denatures ("kills") and removes the collagen from the cells to forbid the tissue from rotting and disintegrating after drying

- optional: substitute part of the alcohol with a mix of booze and a natural alcohol-based ink)

- Glycerine - 200 ml

- lubricant: softens the leather and adds flexibility

- Dish washing lather (eco) - five ml

Tools¶

- Big glass jar, with tight plumbing equipment lid

- to fit all the fish skins

- Blunt scraping tool

- to remove any fish and fatty from the skins

- Large wooden lath

- to dry and stretch the fish skins on

- Hammer and nails

- to nail the fish skins to the board for drying

Yield¶

iii skins

Method¶

-

Preparing the fish skins

- Scrape all the meat, fat and membrane off the fish skins with a blunt scraping tool. Really clean it all off, the skin tin take some handling.

- Wash the fish skins thoroughly with cold soapy h2o (some say to leave information technology for a day to remove slime)

- Rinse the fish skins with cold tap water

-

Prepare the tanning liquid

- Put the glycerine and the alcohol in a glass jar

- Sumberge the fish peel in it and milk shake vigourously for 1 min

- Put a trivial weight on acme if the peel is not submerged (take out before shaking!)

-

Tanning procedure

- Keep the fish skins in the jar for iii days

- Milkshake the jar vigourously for 1 min every few hours, (or at least in one case a twenty-four hour period)

-

Drying procedure

- After three days, accept out the skins (proceed the tanning liquid for side by side fourth dimension)

- Optional: rinse the fish in cold soapy h2o, and rub some boosted glycerine onto the fish (both sides), for a soft, flexible fish leather.

- Nail the skins to the wooden board. This prevents them from curling and shrinking. Don't go far also tight (information technology tin tear at the nails).

- Go out the lath to dry outside, on a balustrade or near an open window.

- When completely dry out, take them off the lath.

Drying/curing/growth process¶

Drying the skins with the scales facing down (towards the wood), results in a smoother surface.

- Mold depth: N/A

- Shrinkage thickness 0-v%

- Shrinkage width/length 0-5%

Shrinkage and deformation control

Nailing them to a wooden board stretches them and prevents shrinkage and crimper.

Curing agents and release agents

N/A

Minimum wait time before releasing from mold A week to dry and reduce the fishy smell.

Post-processing N/A

Further enquiry needed on drying/curing/growth?

Non sure

Procedure pictures¶

Putting the skins inside a jar, Loes Bogers, 2020

Putting the skins inside a jar, Loes Bogers, 2020

Tanning the skins, Loes Bogers, 2020

Tanning the skins, Loes Bogers, 2020

The skins nailed to a board for drying (some patently and some with turmeric alcohol-based ink), Loes Bogers, 2020

The skins nailed to a board for drying (some patently and some with turmeric alcohol-based ink), Loes Bogers, 2020

Variations¶

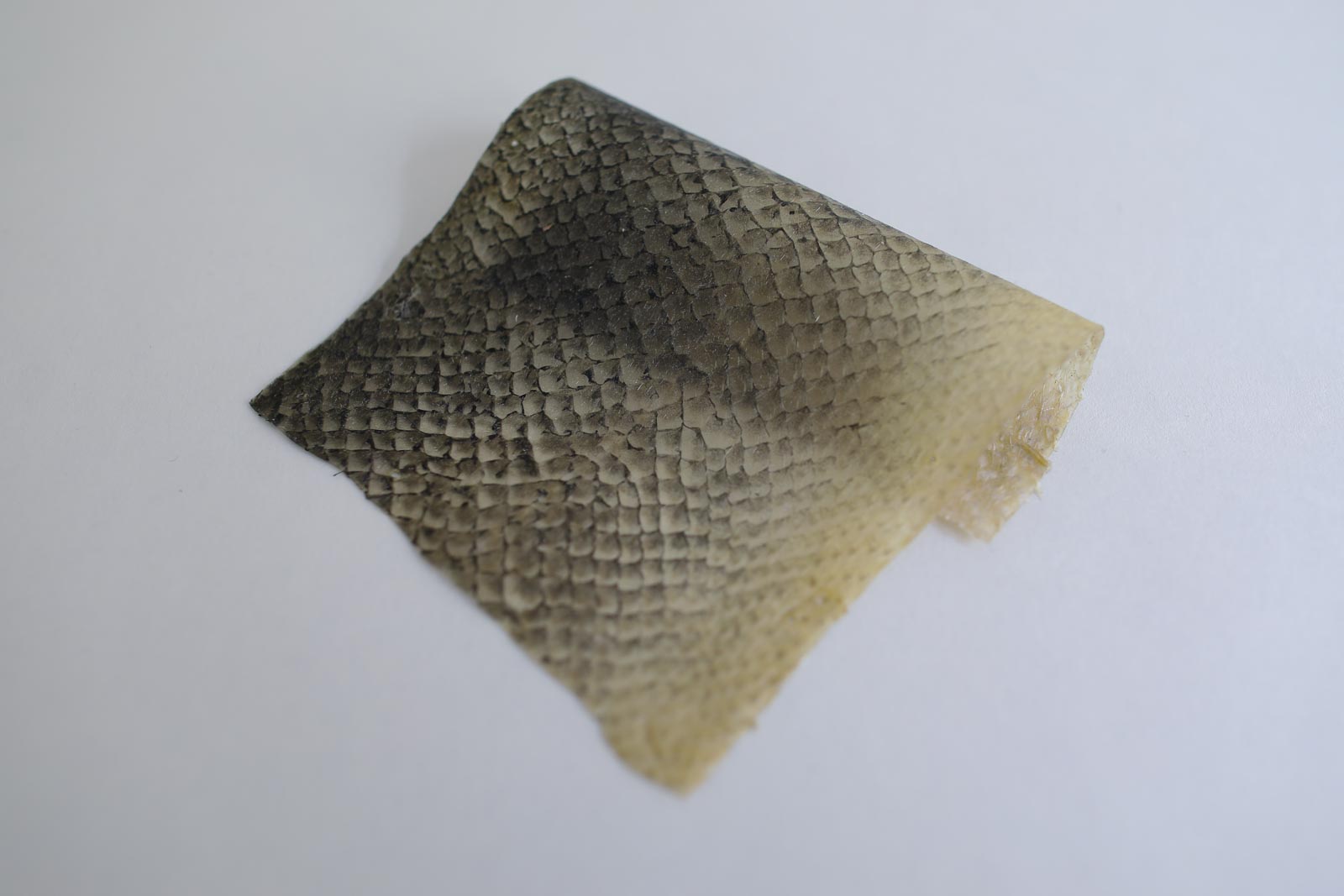

- Add natural alcohol-based colorants to dye the fish skins (e.g. turmeric, hibiscus, or grated beetroot/red cabbage: submerge in alcohol and shake every hr for a day).

- Other softeners to attempt: leather balm, kokosnoot oil, other oils

- Putting a fish skin in the oven for 5-x minutes at depression rut (70 degrees Celcius), it turns highly flexible.

- Make a suede-like soft leather by tanning the fish skins in boiled linseed oil. Add a rock or something heavy to create a lot of friction when shaking the container. Accept the fish out to dry, echo if it is non soft enough. There are several linseed oils out in that location. Raw is often used for outdoors apply and contains less chemicals and petrol-based drying agents but dries a lot slower and can stay sticky. The technique used with raw linseed oil is similar to they way angling nets are impregnated to stand the harsh weather condition at sea.

ORIGINS & REFERENCES¶

Cultural origins of this recipe

Traditional tanning techniques are centuries erstwhile and have been practiced by peoples in most of the Nordic countries (Denmark, Republic of finland, Iceland, Norway), the Joepik in Alaska, the Nanai in Siberia, the Inuit in Canada and Greenland. Information technology is practiced all effectually the world (e.grand. along the Nile in Kenya, in United mexican states and in Australia). Originally, the involved tanning acids from eastward.g. oak and anecdote bark, urine, or alternatively with egg yolk and vegetable oil so cold-smoked over fire to make information technology h2o-proof (also prevents mold and bacteria growth). Alutiiq creative person June Simeonoff Pardue has been credited for this non-traditional tanning process with booze and glycerine. Fish skin tin also be cleaned and stale without tanning.

Needs further research? Non certain

Key Sources¶

- Fish Peel Tanning from the 6-8th form Heritage Kit Curriculum, by Chugachmiut Heritage Preservation, Anchorage, Alaska Usa: link

- Biofabricating Materials by Cecilia Raspanti for Fabricademy 2019-2020: link

Copyright information¶

This recipe was originally published as Fish Peel Tanning in the half dozen-8th course Heritage Kit Curriculum, by Chugachmiut Heritage Preservation, Anchorage, Alaska The states: link

It is unclear if copyright rests on this publication. Farther research is required.

Ethics & SUSTAINABILITY¶

- This technique is strongly associated with indigenous cultures. Using them - specially without crediting it as cultural heritage - is controversial.

- The process is smelly, just the finished product is nearly odorless if done well

- This textile is animal-based (but the production & tanning process is significantly eco-friendlier process than those of e.g. cow hide.

- Denatured alcohol is harsh on pare only not dangerous, don't use on open skin even so.

- Choosing fish that are not locally abundant or known to be overfished is considered problematic. Try to find fish from sustainable fishing industries, and fish that is in-season, or the bycatch from local angling industry.

Sustainability tags

- Renewable ingredients: yes

- Vegan: no

- Made of by-products or waste: yes

- Biocompostable final product: yes, but only professionally (home composting of brute-based materials is not allowed in the European union)

- Re-employ: the tanning liquid can exist reused

Needs further research?: Not certain

Fish skins are considered a waste product of the line-fishing industry and are often trashed as many people tend to favour fish fillets without skin.

Properties¶

- Strength: strong

- Hardness: variable

- Transparency: translucent

- Glossiness: matt

- Weight: light

- Structure: closed

- Texture: rough/medium

- Temperature: warm

- Shape memory: high

- Scent: moderate (afterward thorough drying)

- Stickiness: depression

- Weather resistance: needs farther inquiry

- Audio-visual properties: needs further inquiry

- Anti-bacterial: needs further research

- Non-allergenic: needs further inquiry

- Electric properties: needs further inquiry

- Estrus resistance: depression

- H2o resistance: waterproof/needs further research on stitching methods

- Chemical resistance: needs further enquiry

- Scratch resistance: loftier

- Surface friction: medium/variable

- Color modifiers: none

ABOUT¶

Maker(southward) of this sample

- Name: Loes Bogers

- Amalgamation: Fabricademy student at Waag Textile Lab Amsterdam

- Location: Rotterdam, the Netherlands

- Appointment: 24-02-2020 – 02-03-2020

Environmental conditions

- Humidity: 40-50%

- Exterior temp: 5-11 degrees Celcius

- Room temp: eighteen – 22 degrees Celcius

- PH tap water: 7-viii

Recipe validation

Has recipe been validated? Yes, by Cecilia Raspanti, TextileLab, Waag Amsterdam, 9 March 2020

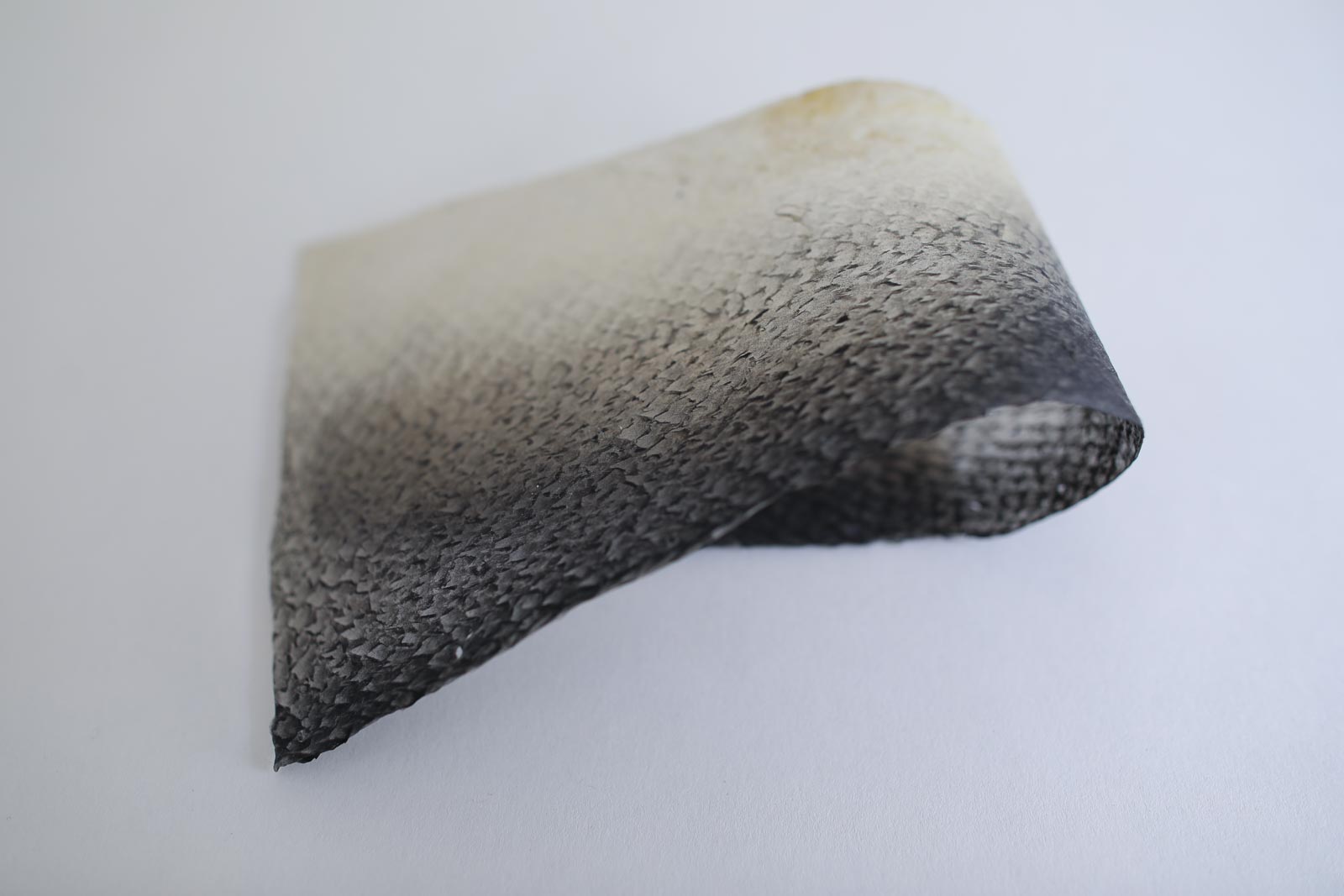

Images of the final sample

Tanned salmon skin (no colorant, glycerine softener), Loes Bogers, 2020

Tanned salmon skin (no colorant, glycerine softener), Loes Bogers, 2020

Tanned salmon skin (no colorant, glycerine softener), Loes Bogers, 2020

Tanned salmon skin (no colorant, glycerine softener), Loes Bogers, 2020

Tanned salmon skin (no colorant, no softener), Loes Bogers, 2020

Tanned salmon skin (no colorant, no softener), Loes Bogers, 2020

Tanned salmon skin (dyed with turmeric, no softener), Loes Bogers, 2020

Tanned salmon skin (dyed with turmeric, no softener), Loes Bogers, 2020

Tanned salmon pare (dyed with turmeric, glycerine softener, Loes Bogers, 2020

Tanned salmon pare (dyed with turmeric, glycerine softener, Loes Bogers, 2020

REFERENCES¶

- Fish Skin Tanning from the 6-8th grade Heritage Kit Curriculum, by Chugachmiut Heritage Preservation, Anchorage, Alaska USA: link

- Interview with skin sewer June Pardue by Anchorage Museum & Smithsonian Arctic Studies Centre on Youtube, 16 January 2015: link

- Making Leather from Fish Skins by Eva Hopman, for Hunebed Café, north.d.: link

- Biofabricating Materials by Cecilia Raspanti for Fabricademy 2019-2020: link

- Bio Materials by Laura Luchtman for Textile University, 14 November 2016: link

- Preservation of Fish Nets past Harden Franklin Taylor, U.S. Bureau of Fisheries, 1920: pp. 22-26: link

Source: https://class.textile-academy.org/2020/loes.bogers/files/recipes/fishskin/

Posted by: dugasshoult.blogspot.com

0 Response to "How To Tan Salmon Skin"

Post a Comment